Data Services & APIs

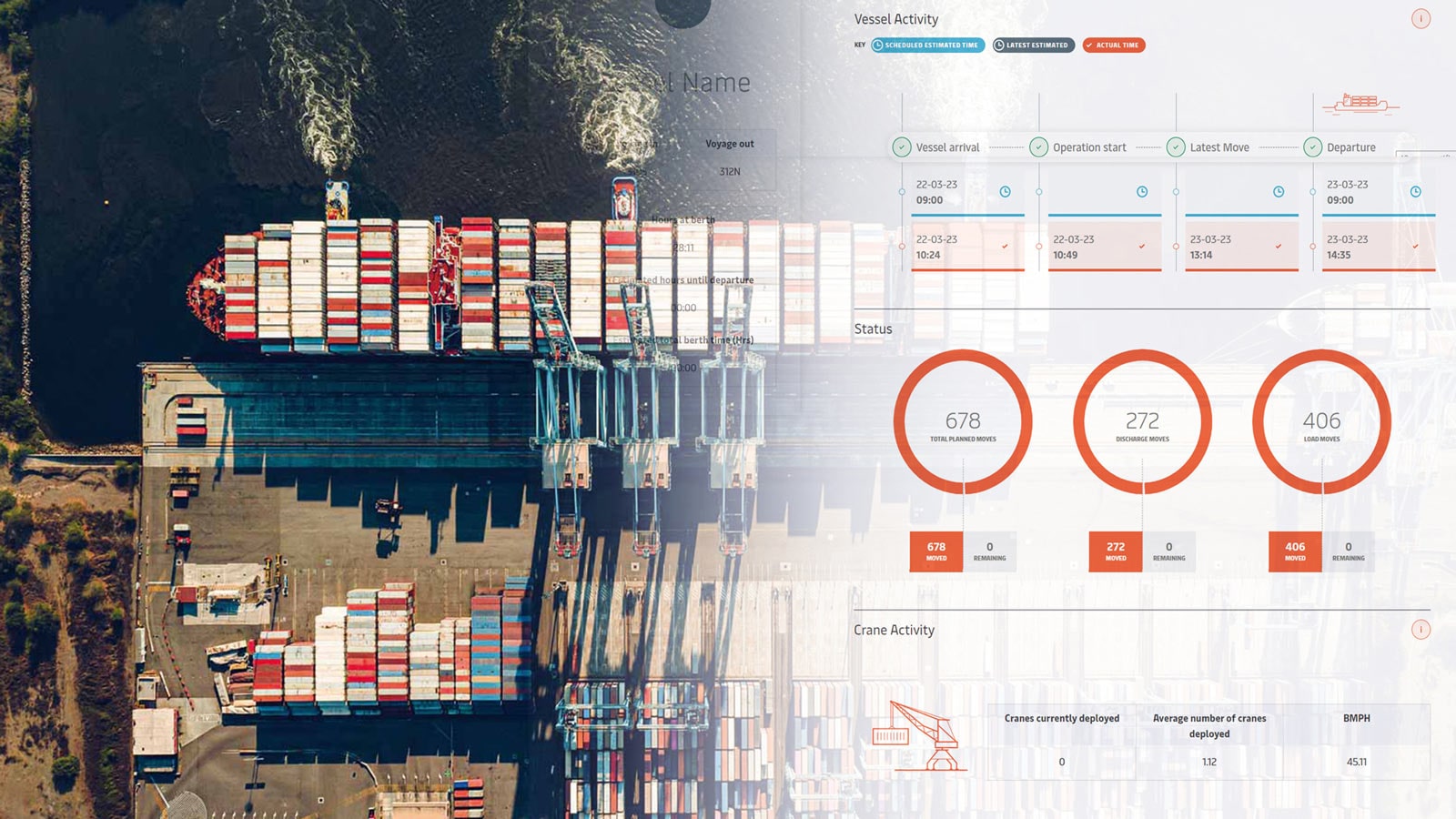

Our modern, standardized application programming interfaces (APIs) are a secure and cost-effective way to access your container, vessel or appointment data in real-time.

We believe that our people and our customers will benefit from an automated digitized and connected terminal experience. This is built on a modern and standardized IT infrastructure and that better connects our physical and digital assets. The result is improved safety, reduced carbon emissions, and providing customers with access to real-time data.

Digital transformation initiatives will enable us to better serve our customers in a more cost effective and efficient manner. We are introducing Value Added Services that improve our customers experience and supports their changing logistics needs.

Installing Internet of Things (IoT) sensors and devices on our equipment (Over 2,500 pieces as of 2022) is revolutionizing terminal operations. This solution is enabling us to monitor and visualise asset performance in real time, detect operational exceptions as they occur, and provide standardised tools and processes to respond to these.

Our customers don’t want to deal with paper. Now, edge computing with Internet of Things sensors on equipment, that incorporate computer vision and AI can give customers what they’ve longed for, for some time – almost instant access to cargo data upon arrival as well as automated repairs or fixes.

Near real-time Edge computing with IoT sensors that incorporate computer vision and AI will give customers what they’ve longed for some time - almost instant access to cargo data upon arrival, as well as automated repairs or fixes. The software can then decide whether there’s an intervention needed, such as maintenance or repair, and that information is released to the customer. Cameras and data collection devices will be installed throughout terminals, via private 5G networks, to monitor for anything, be it theft, lost cargo, or potentially unsafe conditions.

All of this information opens new opportunities for digital solutions that keep customers updated and aid real-time decision making to speed up their supply chain. Watch this space!

Our Way of Working introduced in 2018 has enabled us to develop standardised global solutions which also offer local flexibility to accommodate market needs. This global approach to development means we can significantly speed up the roll-out of industry leading, digital solutions that were developed based on best practices from around the world.

Asset Digitization – Applying the Internet-of-Things to connect all equipment and processes (We added sensors/devices to over 2500 pieces of equipment in 2022)

Artificial intelligence to reliably predict events instead of waiting for them to happen e.g Estimated vessel departure times

Edge computing for near real-time data analysis to optimise container handling equipment and cloud based computing for less time sensitive analysis

Private 5G/6G and satellite connectivity for reliable and fast connectivity across our terminals, and a powerful edge computing foundation

Modular automation where the biggest value can be achieved for customers and the terminal e.g. automated gates or crane support features

A standardised, proactive and coordinated approach to Asset Maintenance

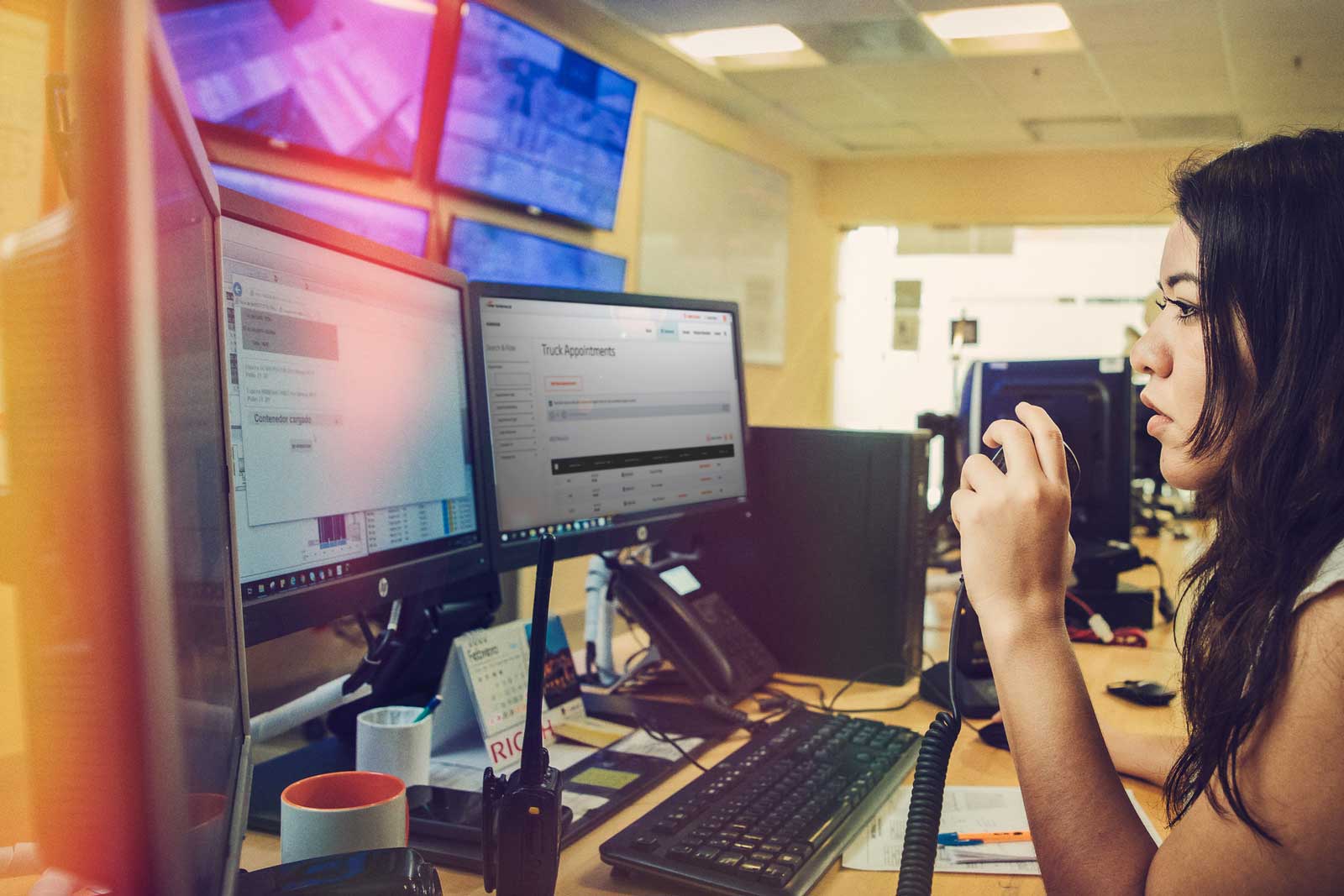

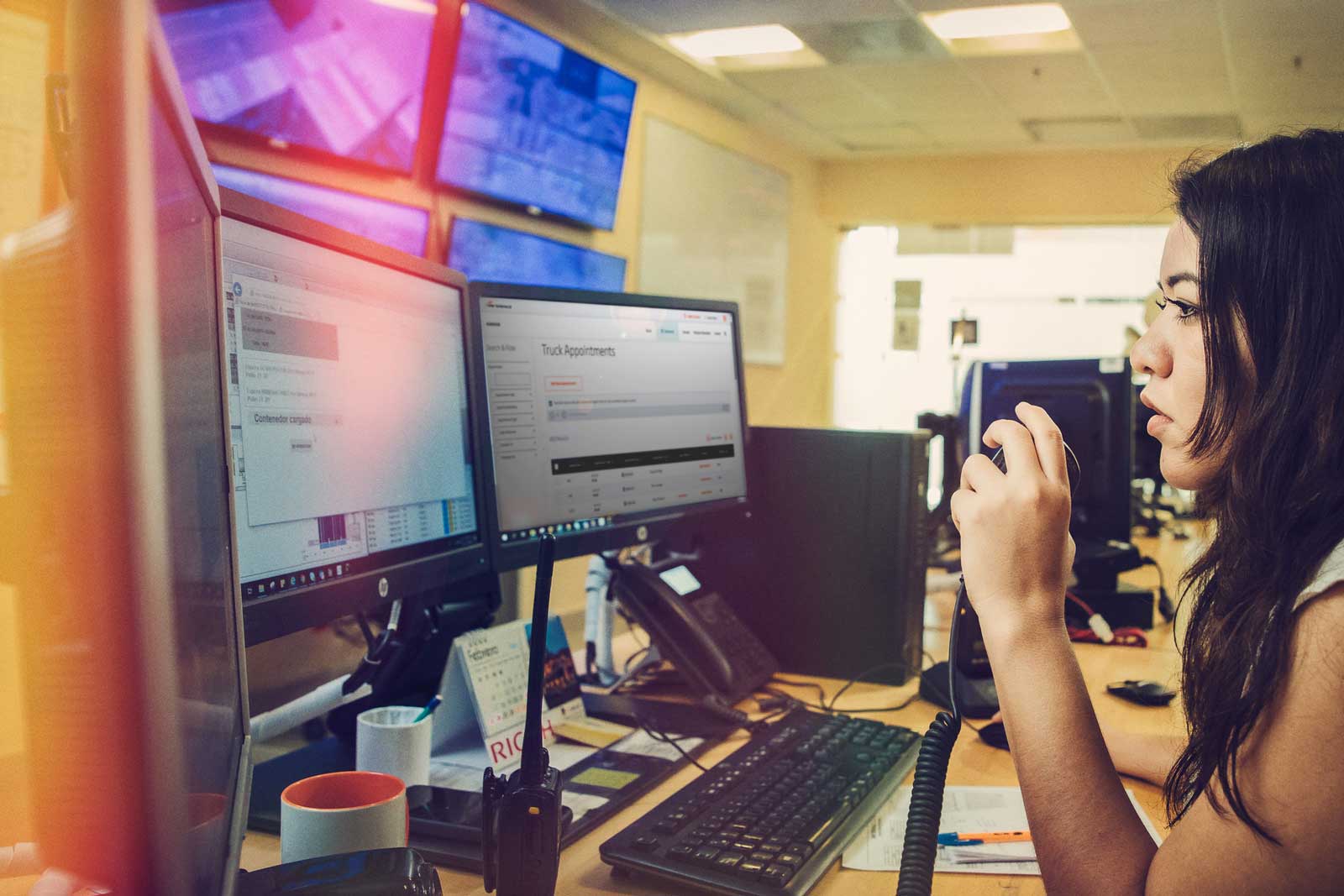

Terminal Operating System upgrades which leverage global best practices and have centralised 24/7 predictive monitoring

Augmented reality to make safety training as realistic but low risk as possible

Our modern, standardized application programming interfaces (APIs) are a secure and cost-effective way to access your container, vessel or appointment data in real-time.

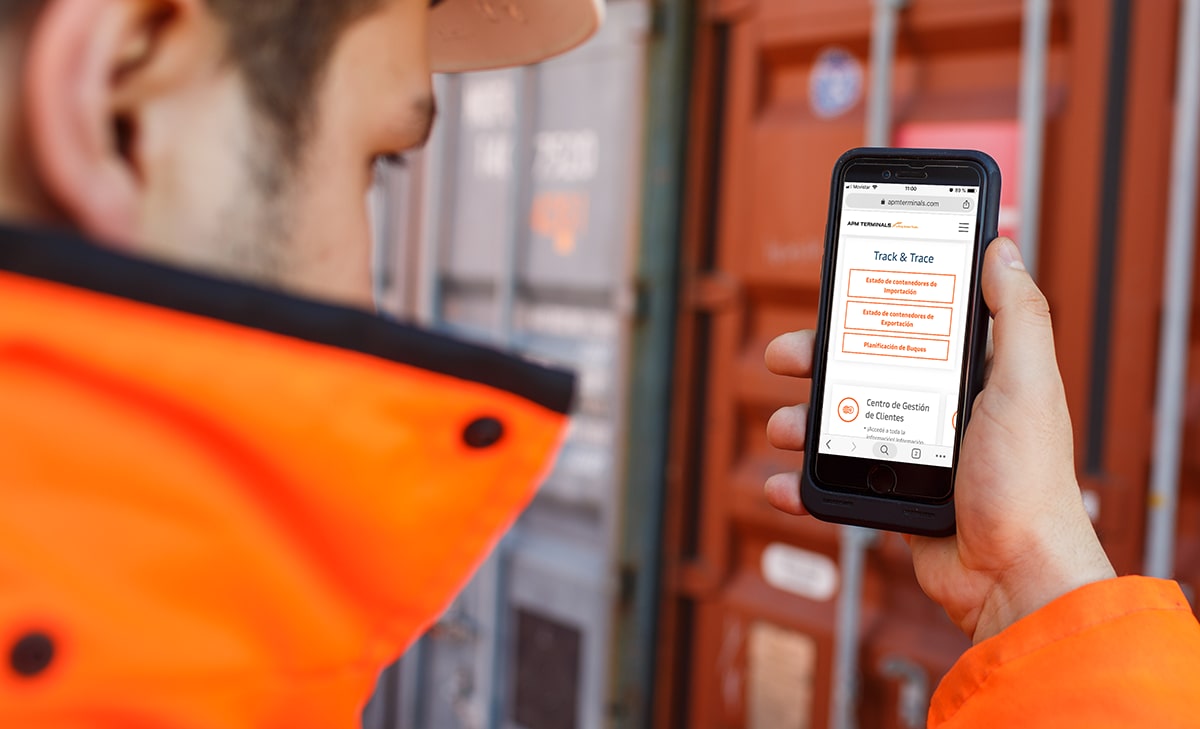

Check the status of your container or vessel, save containers to a Watchlist or set email notifications via our global Track & Trace.

Requests services ranging from Fumigation to Container Photos and Break Bulk to VGM online in just a few clicks.

APM Terminals' global customer alert system enables customers to register to receive Operational Alerts via SMS or email.

View current turn times in real-time, as well as hourly data for the past 24 hours and average daily Truck Turn Times for the last 30 days.

With a pre-scheduled pick up, your container will be waiting for you on arrival, not the other way around.

One secure place to securely store, search and track your hazardous cargo documentation - with fast and intuitive upload - soon to be supported by Artificial Intelligence. This is exactly what APM Terminals’ Hazardous Documentation Vault provides.

The Shipping Line Dashboard provides real-time, 24/7 visibility of container loading/discharging from anywhere in the world.

The best digital tools and solutions are developed collaboratively with our customers. If you're missing something that can make your life easier, let use know via digital@apmterminals.com.